Dates are an integral part of many Middle Eastern cultures, symbolizing Arabian hospitality and prosperity. The date palm’s fruit has been consumed in this part of the world for thousands of years due to its nutritious value and nourishing properties. The UAE produces 750,000 tonnes of dates annually, or 14 per cent of the total global output. The fruit is eaten in its raw form, but together with its pit, it is used to manufacture sweeteners, coffee, and cosmetics. Now, Sara Abou Farha, an architect and town planner, and her husband Khaled Shalka, an engineer, are focusing on the by-product of date stoning, to create the first date seed cement, Datecrete, and have also created the first table made using date seed.

The design duo has been studying date seeds for several years and came to the idea of experimenting with them as a cementitious product. “Date seeds are a wasted by-product of the date farming industry,” Abou Farha says. “As far as we know, apart from a small amount being given away to farmers who are interested in using them as cattle feed, the majority of date seeds produced are discarded daily.” The number of date seeds being thrown away is staggering. On an average day in the UAE, just one farm discards up to 15 tonnes of date seeds each day, an incredible amount if you consider that the constituents of date seeds are the same as wood, in different ratios. “Considering it shares the same properties of wood, wasting date seeds is akin to discarding tens or hundreds of tonnes of perfectly usable wood each day, just here in the UAE,” says Abou Farha.

With this in mind, the couple further explored the process of using data seeds to create structures. This led to the exploration of using the seeds to produce a mouldable cement-like material. Their work received acknowledgement and Tashkeel selected the couple for its Tanween 2022 program in January this year. The generous funding from Tashkeel allowed the pair to continue their research and develop their idea.

Previously, academic researchers in the MENASA region have worked on the application of date palm seeds as a suitable filler material in glass-epoxy composites as well as a coarse aggregate in concrete production. What sets Abou Farha and Shalka’s product apart is that the duo has created the world’s first date seed-based cementitious material that contains no trace of resin or cement. “The material is currently under patent pending so I can’t tell you too much about how Datecrete is produced, however, we are using ground date pit powder, along with a chemical mix we developed when studying early regional building technology that predates the arrival of Portland cement. These components are mixed with water and cast into moulds.”

“It is important to note that Datecrete contains no trace of cement or concrete or resin, but is a wholly new material,” Abou Farha continued. “It is cementitious in quality, so it moulds into an endless variety of shapes just like traditional cement does. However, Datecrete outperforms concrete in flexural and compressive strength, according to official lab tests, while being less dense, too. Simply put, it is a sustainable and biodegradable alternative to concrete.”

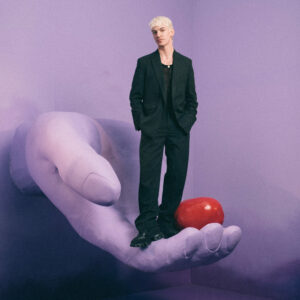

The duo has also designed a table and mirror furniture piece in Datecrete that debuted in Downtown Dubai last month and Abou Farha and her husband are looking forward to creating more designs. “I mentioned earlier that Datecrete moulds into an endless variety of shapes, just like concrete,” she said. “It’s safe to say it can do anything that traditional concrete does – outdoor and interior furniture, house footings, domestic house floors, external paths and walkways.”

It will be interesting to follow Datecrete studio and this husband and wife team on their journey as they develop more designs using Datecrete. With the sustainable material sharing the same properties as concrete perhaps in time, we’ll see construction companies utilize it in Dubai’s next phase of high-rise buildings.